The Brunkeberg System

A new generation of vertical logistics

New Construction

Revolutionizing Vertical Logistics

The patented Brunkeberg® System revolutionizes building construction by incorporating vertical rails onto the exterior façade, offering a cutting-edge turnkey solution that accelerates and enhances the safety of panel installation and material handling on construction sites. This innovative system enables the seamless and secure installation of oversized panorama windows, facilitates automated cleaning, and simplifies future upgrades, setting a new standard for efficiency and functionality in the construction industry.

Beyond improving installation speed and safety, the Brunkeberg® System delivers transformative benefits to construction projects. By freeing up valuable ground space, reducing reliance on lifting resources, and minimizing debris and waste, it streamlines operations and enhances site productivity. Additionally, it eliminates the need for interior storage of exterior panels, further optimizing site logistics. Remarkably, the Brunkeberg System has the potential to compress the entire construction schedule, shortening project timelines by several months and delivering substantial cost and time savings.

Brunkeberg

System Benefits

- Oversized glazed façade panels

- Cost savings

- Automated installation system

- System expansion including window cleaning and marketing banners

- Sequential lean construction

- Less environmental impact

Engineering

Specific Benefits

- Integrated logistic solution plus our containers, capable of delivering all building materials

- Semi-automatic system which is fully scalable

- Dedicated own lifting system

- Secure lifting - can lift façade elements and containers in windy conditions

- Minimum need for “on slab” intermediate storage capacity means floors are clear and material logistics can be substantially improved

Brunkeberg has developed a novel solution to effectively address one of the biggest deficiencies that has plagued the mid- and high-rise construction industry for more than a century. The ability to introduce cost and logistic efficiencies to panel installation and maintenance is a true game changer.

Our Solution is

Faster

Save Months

- Accelerated gpanel installation process

- Reduced facade installation personnel

- Shortened panel offloading time

The Brunkeberg system streamlines facade installation, enhancing both speed and safety. By optimizing resources—such as ground space and lifting equipment—the overall project timeline can be shortened by several months.

Safer

Track secured access

- Minimized weather dependency

- Reduced damage and labor demands

- Lower health and safety risks

Integrated vertical tracks provide secure access throughout the building’s lifecycle, supporting installation, maintenance, and facade replacement. This system also mitigates delays and damage caused by adverse weather conditions, particularly high winds.

smarter

Multifunctional tracks

- Automated facade cleaning

- Integrated banner advertising

- Enhanced architectural design

The Brunkeberg system’s tracks support a variety of services, including automated cleaning, simplified upgrades, and advertising. Additionally, the system accommodates architectural enhancements such as sun shading or solar panel installations.

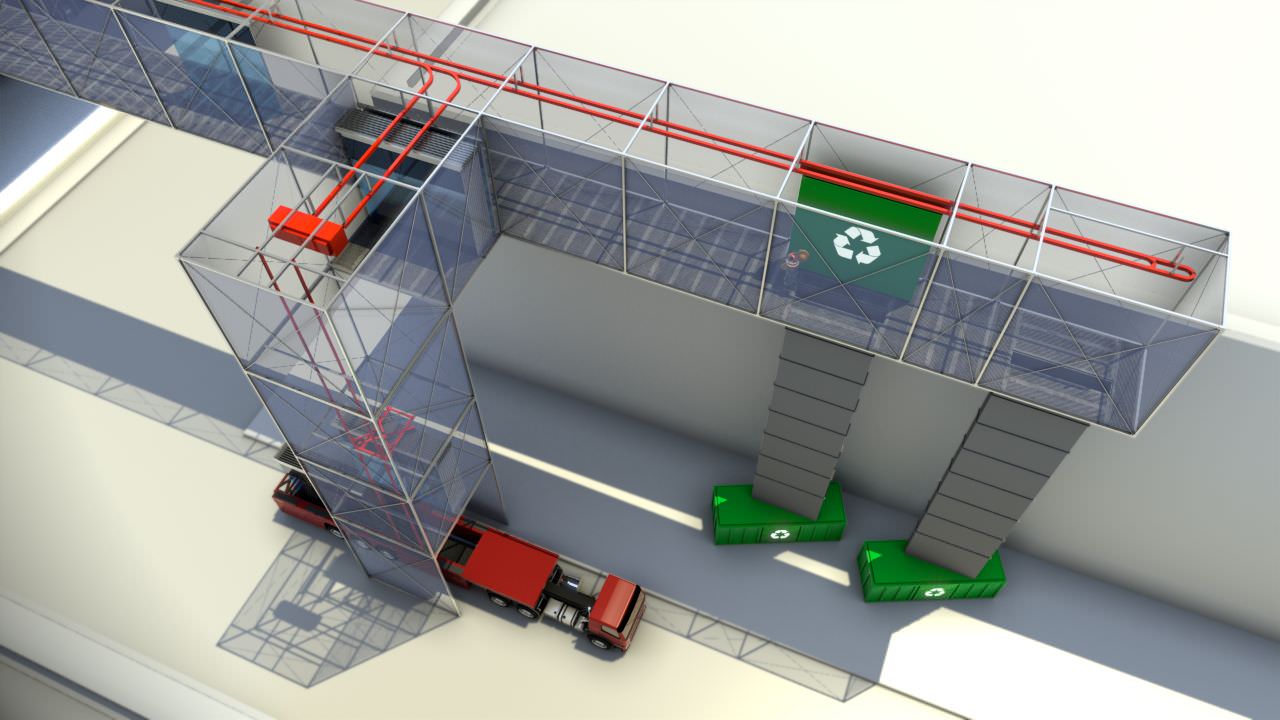

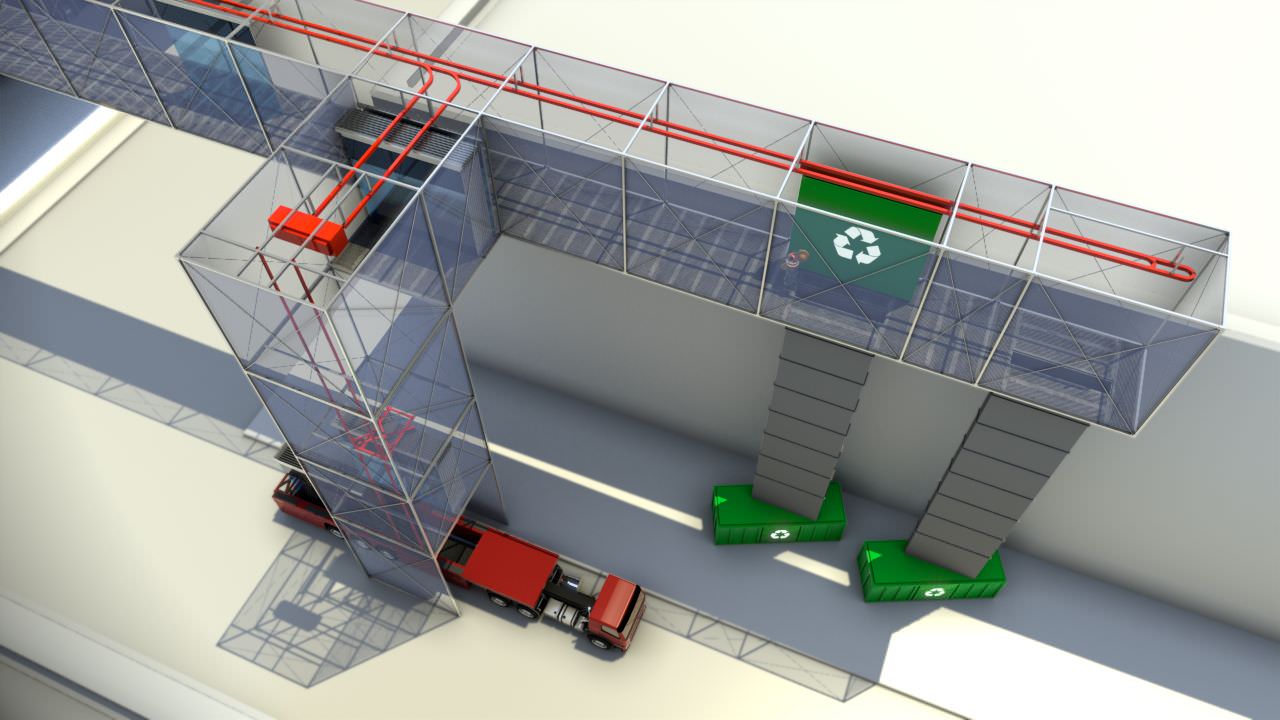

Re-cladding

Facade Replacement with less tenant disturbance

Facade replacement typically means the building needs to be vacated for a substantial period of time, and the tenants need to be relocated at tremendous cost and inconvenience. With The Brunkeberg® System, this inconvenience is minimised as the re-clad process works floor by floor.

Debris, glass and metal from the old curtain wall are returned on the exterior of the building using our track system. This makes removal and recycling more cost effective, faster and safer.

Facade replacement typically means the building needs to be vacated for a substantial period of time, and the tenants need to be relocated at tremendous cost and inconvenience. With The Brunkeberg® System, the tenants can remain in the building while the re-cladding takes place floor by floor.

Debris, glass and metal from the old curtain wall are returned on the exterior of the building using our track system. This makes removal and recycling more cost effective, faster and safer.

More than just a render

800kg glass panels installed in minutes

Internally referred to as the Örebro Technical Facility this building is the new Scandinavian headquarters for KTM Motorcycles.

Here we gave a live demonstration of the Brunkeberg System to over 150 guests showcasing how just two men could distribute and instal 800kg glass panels in less than 5 minutes per panel.

Other Services

What further sets Brunkeberg apart from the competition and potentially turns the company into a real game-changer is that once the unique Brunkeberg Wind Post has been installed, this opens limitless opportunities to apply Brunkeberg’s value-add solutions.

These can drastically simplify construction logistics, lower lifecycle costs for buildings through services such as automated window cleaning, make maintenance more efficient, provide energy savings and, in the end, allow for truly unique ways of re-cladding (refurbishing) old façade:

The Brunkeberg Automated Facade Cleaner AFC:

A sustainable energy efficient surface cleaning system that utilizes the installed Brunkeberg rail structure. It's driven by gravity, operating without dependence on any external supply of water, chemicals and power.

Compared to traditional facade cleaning systems, the Brunkeberg AFC will allow for faster and more efficient cleaning system.

The Brunkeberg Rail Hanging System (RHS):

This unique system utilizes the installed Brunkeberg rail system for hanging banners directly on the facade for advertising, installation of sunscreen systems, photovoltaic systems, etc.

The Brunkeberg Sliding Wall:

With traditional building methods, construction work is often delayed due to bad weather. Utilizing the Brunkeberg Sliding Wall, the contractor doing interior work on any given floor can easily continue working without any interruption from changing weather conditions, nor risk of damage to expensive materials or machinery.

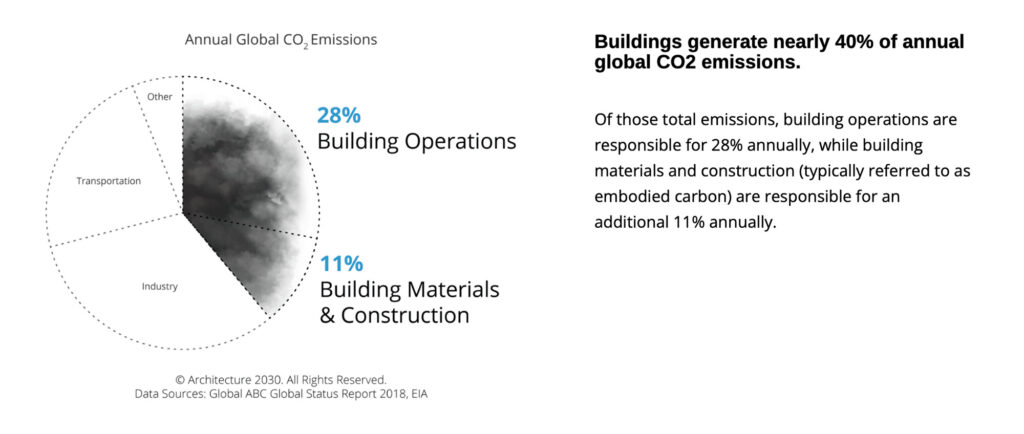

The Sustainable Choice

Brunkeberg Systems AB is committed to be part of lean construction which contributes to lowering global CO2 emissions within the building industry.

Lean Construction Principles

Flow of Work Processes

The ideal state of a lean construction project is a continuous, uninterrupted workflow that is reliable and predictable. The sequence is key in construction. With Brunkeberg’s track system and logistical off-loading stations, flow of work will increase and become more efficient, hence, saving time, materials, and money.

Working with the right materials

Brunkeberg will strive to work with manufactures such as Lindner SE which uses aluminum produced in Norway and Iceland with least environmental impact.